- Sunderland becomes a focal point for the UK’s electric vehicle revolution with a £1 billion investment by AESC in a new gigafactory.

- The plant is expected to create over 1,000 jobs and increase UK electric vehicle production to 100,000 units annually.

- The project benefits from £680 million in state-backed financial guarantees and £320 million in private funding.

- The new facility significantly eclipses the existing factory, aiming for a capacity of 15.8 GWh.

- This investment is part of a broader Industrial Strategy to boost innovation and sustainable transport across the UK.

- By fostering partnerships, the initiative aims to dynamically impact job creation, supply chains, and UK decarbonization goals.

- Sunderland’s plant represents progress and resilience, positioning the UK prominently in battery manufacturing.

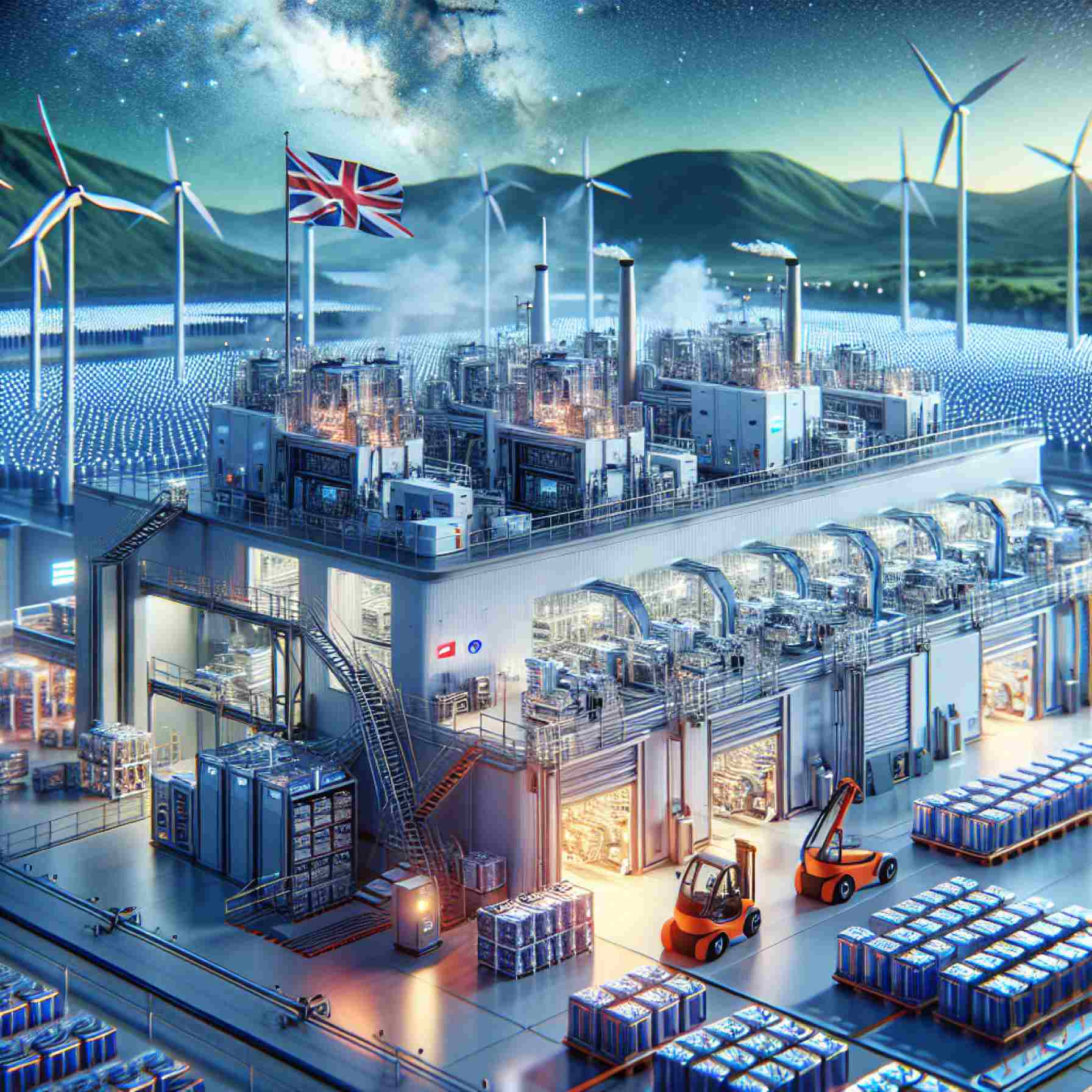

A leap towards a greener future is taking shape in the historic city of Sunderland, where verdant hills meet the industrial past. The £1 billion infusion—around $1.3 billion—by AESC into a new electric car battery plant marks a pivotal point in Britain’s bid to revolutionize its electric vehicle landscape.

As the cold North Sea wind swirls through Sunderland, the prospect of warmth and prosperity heralded by this investment becomes palpable. This colossal gigafactory is poised to supercharge the nation’s electric vehicle ambitions, projected to breathe life into more than 1,000 jobs. Like a phoenix rising, it promises to boost production to 100,000 electric vehicles annually—sixfold the UK’s current capacity.

This monumental endeavor isn’t a solo pursuit. It thrives on a sophisticated tapestry of partnerships, with the state and private sectors entwining their resources. Financial guarantees from state bodies such as the National Wealth Fund and UK Export Finance unlock a robust £680 million, supplemented by £320 million in private finance and strategic business equity.

Sunderland knows manufacturing, having housed an AESC factory with a 1.8 GWh capacity. Yet, this new facility dwarfs its predecessor, projecting a vision of up to 15.8 GWh when it hits full stride. Within this grand ambition lies the promise of more than just physical batteries; it’s a conduit for advanced innovation and sustainable transport transformation.

The implications ripple beyond technology—a modern Industrial Strategy aiming to ignite high-potential sectors in every UK corner. It’s more than metal and circuitry; it’s an echo of economic vitality reaching far and wide, reflecting hopes of fueling progress while reinvigorating local communities with well-paid jobs.

For AESC, the investment marks a significant stride in backing the UK’s march toward a decarbonized future. It’s a clear call to action: accelerate the transition through partnerships, creating sustainable, high-quality jobs and supply chains in the bargain.

This impressive milestone isn’t just about electrifying vehicles. It’s about driving social change, nurturing ecosystems of growth, and positioning the UK as a formidable player on the battery manufacturing stage. With shared purpose and collaboration, Sunderland’s plant becomes a symbol of resilience and innovation—bringing shades of prosperity and excitement to Britain’s industrial horizon.

Sunderland’s Gigafactory: UK’s Bold Step into a Greener Future

Expansion of Sunderland’s Industrial Landscape

AESC’s hefty £1 billion (approximately $1.3 billion) investment into the electric car battery plant in Sunderland marks a transformative chapter for both the city and the broader UK’s electric vehicle ecosystem. As this cutting-edge gigafactory comes to life, the initiative mirrors not just an industrial upswing, but also a leap towards a sustainable and innovative future.

Key Features and Projections

1. Enhanced Production Capacity: When operational, the new gigafactory in Sunderland aims to produce batteries for up to 100,000 electric vehicles annually, significantly amplifying the UK’s current production potential. This facilitation of large-scale electric vehicle manufacturing is set to invigorate the local economy and the UK’s green ambitions.

2. Job Creation and Economic Impact: More than 1,000 high-quality, sustainable jobs are anticipated, underscoring a significant social and economic shift in Sunderland. This could play a pivotal role in revitalizing the local community and boosting economic activity.

3. Innovative Collaborative Effort: The venture is supported by a fusion of public and private sector resources. The UK government’s financial tools, alongside private investment, represent a complex web of financial and strategic partnerships aimed at fortifying the UK’s industrial stature.

Real-World Use Cases and Benefits

– Boosting Local Economies: This project symbolizes a renaissance for industrial regions such as Sunderland, infusing capital and opportunities into areas historically reliant on traditional manufacturing.

– Driving Technological Advancements: As the plant scales production, it may become a nexus for battery innovation, potentially propelling advancements in electric vehicle technology and sustainability.

– Stimulating Environmental Change: With its focus on green technology, the plant contributes significantly to reducing carbon emissions and advancing the UK’s commitment to environmental targets.

Market Forecasts and Industry Trends

– Growth of Gigafactories in Europe: Sunderland’s gigafactory reflects a broader trend of increasing gigafactory investments across Europe. These facilities are critical for satisfying the accelerating demand for electric vehicles and their components.

– Decarbonization as a Strategic Focus: This project is a testament to the UK’s broader commitment to decarbonization and positioning itself as a leader in electric vehicle technology.

Controversies and Limitations

– Economic and Resource Allocation Concerns: While the investment heralds a new age of industrial rejuvenation, it also raises questions regarding land use, energy consumption, and geopolitical dependencies on battery materials.

– Long-term Sustainability: While immediate job creation is a boon, maintaining these roles and the plant’s economic viability poses a long-term challenge.

Actionable Recommendations

– Shaping Local Education Initiatives: Emphasize local educational programs tailored to equip the workforce with necessary skills for emerging electric vehicle technologies.

– Sustainable Energy Usage: Ensure the plant’s operational model prioritizes renewable energy sources, in line with its sustainability mission.

– Community Engagement: Foster robust local partnerships to integrate community concerns into the project’s long-term strategies effectively.

For more information on electric vehicle initiatives and sustainable energy practices, visit the Nissan and UK Government websites.